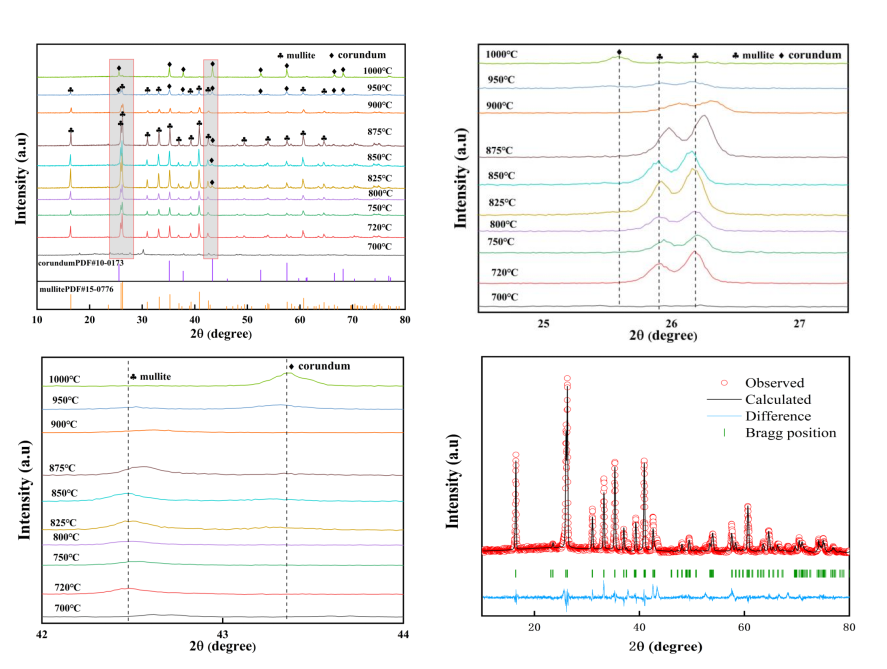

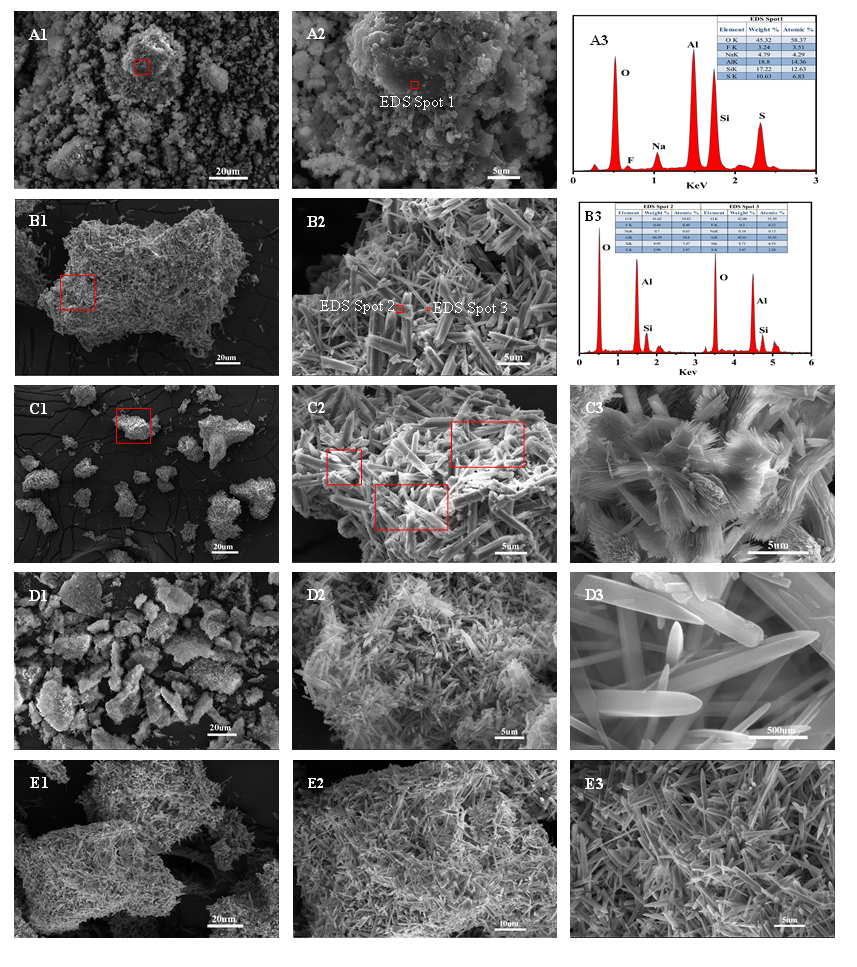

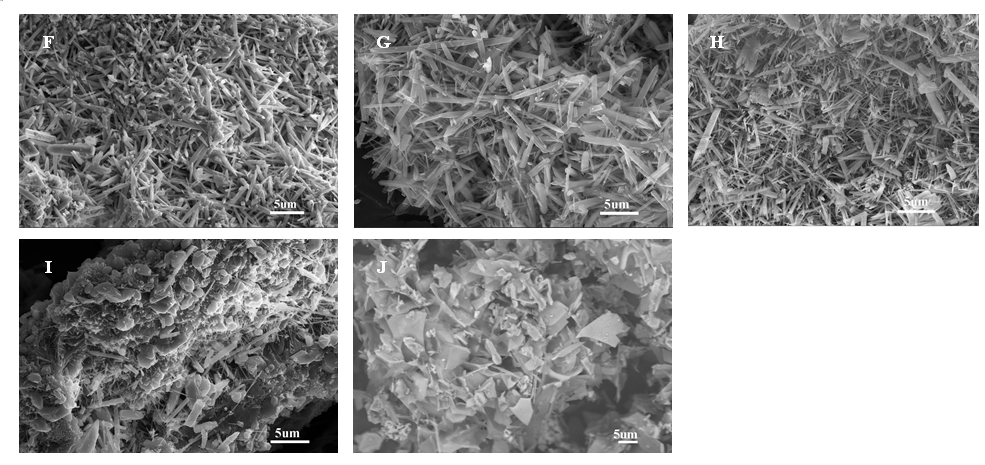

近日,能源与建筑环境学院顾晓华课题组在Ceramics International的Top顶刊上发表了题为Industrial waste silica-alumina gel recycling: low-temperature synthesis of mullite whiskers for mass production的研究论文。该研究开创实现工业废硅铝凝胶成功回收,揭示了由工业废硅铝凝胶低温合成晶须产业化过程及制备机理,发现了一个新颖的低温合成晶须的绿色制备方法。研究结果显示以工业废硅铝凝胶和硫酸铝为原料,AlF3·3H2O和Na2SO4为助剂,采用气-液-固(V-L-S)法制备了高纯度莫来石晶须(图1)。采用XRD、TG-DTA、SEM等手段研究了烧结温度对莫来石化反应和莫来石形貌的影响(图2-图7)。结果表明:AlF3·3H2O和Na2SO4的引入改变了莫来化反应的路径,使莫来化反应的初始温度达到720℃;SEM结果表明,当烧结温度从720℃升高到825℃时,莫来石晶须由二次生长向各向异性生长转变。

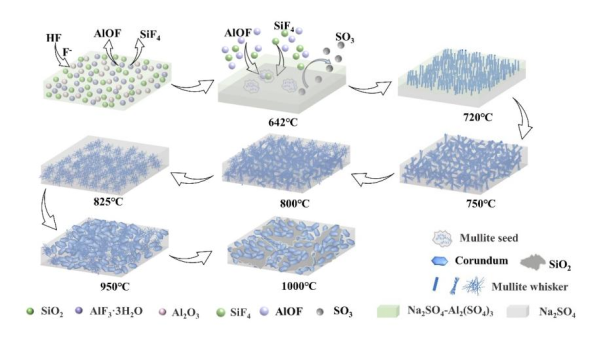

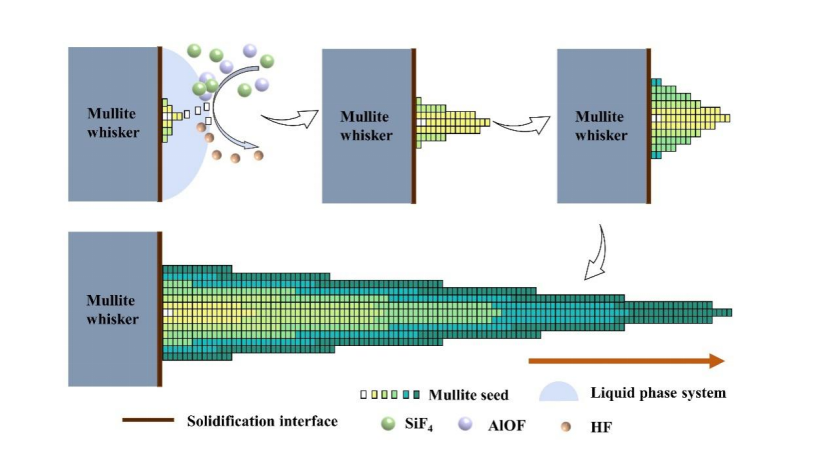

通过分析,提出了以Na2SO4为液相模板的AlF3辅助莫来石晶须生长的“溶解-沉淀”过程机理(图8)。

该研究成果不仅成功探索了绿色低温固废胶渣制备莫来石晶须的制备方法,而且揭示了熔盐法制备莫来石晶须的机理。本研究提出了一种新颖可行的富硅工业废弃物回收利用方案,为工业废弃物的高附加值回收利用提供了新的简单见解,为莫来石晶须的实际批量生产提供了新的思路。

本文的工作受到中石化齐鲁催化剂公司的支持。晶须扫描和衍射数据测试得到了上海交大测试工作人员的帮助。

Fig. 1 The preparation process of the mullite whisker.

Fig. 2 XRD patterns of samples sintering at different temperatures. (a) shows the full temperature change; (b) and (c) shows a representative change. (d) Rietveld refinement of X-ray powder diffraction data for E sample showing the observed (red circle) and calculated (solid black line) intensities, the calculated Bragg reflections (green tick marks), and the difference (solid blue line).

Fig. 3 SEM micrographs of samples sintering at different temperatures (A1-700 °C, A2-700 °C, A3 EDS analysis spectrum of the whisker from A2; B1-720 °C, B2 are the magnified SEM images of B1, B3 EDS analysis spectrum of the whisker from B2; C1-750 °C, C2 are the magnified SEM images of C1; C3 SEM shows the fine mullite whiskers that have been decomposed from the coarse whiskers; D1-800 °C, D2-800 °C, D3-800 °C; E1−825 °C, E2 and E3 are the magnified SEM images of E1.

Fig. 4 SEM micrographs of samples sintering at different temperatures (F-850 °C, G-875 °C, H-900 °C, I-950 °C, J−1000 °C).

Fig. 5 The morphological evolution model of mullite whiskers at different sintering temperatures.

Fig. 6 TEM characterization of mullite whiskers of sintered samples at 800 °C. (a, d) TEM image of a single mullite whisker; (b) HRTEM image; (c) The SAED of mullite whiskers. (e) shows the crystal structure of mullite along the [001] direction.

Fig. 7 TG-DTA curve of the samples in nitrogen atmosphere.

Fig. 8 The scheme of vapor-liquid-solid (V-L-S) growth mechanism of mullite using AlF3·3H2O assisted Na2SO4 molten salt method.

文章链接